What Is SPC Flooring

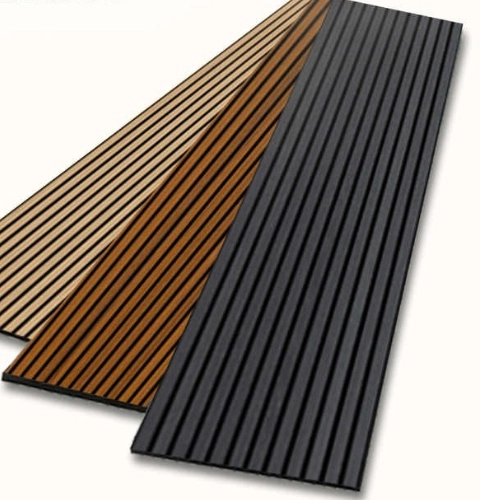

SPC flooring, a cutting-edge vinyl flooring solution, is engineered from stone polymer composite materials, ensuring exceptional durability and resistance to both moisture and wear. This innovative flooring option is highly favored in both residential and commercial settings due to its ease of installation and low maintenance requirements.

Our SPC flooring stands out for its superior quality, utilizing 100% virgin material to guarantee unparalleled durability and long-lasting aesthetic appeal. Crafted to meet stringent heavy-duty performance standards, our flooring not only delivers enduring beauty but also enduring functionality.

Why hesitate? Contact us today to request your complimentary samples and discover firsthand why our SPC flooring is a preferred choice among discerning customers.

SPC flooring specification | |

Color | Several hundreds of color available |

Thickness | 4mm SPC flooring |

Size: | 1200 x 184 mm, 912x150mm ,930x310mmetc. |

Top wearlayer | 0.3mm, 0.5mm |

Special treatment | Painted V-groove, soundproof IXPE |

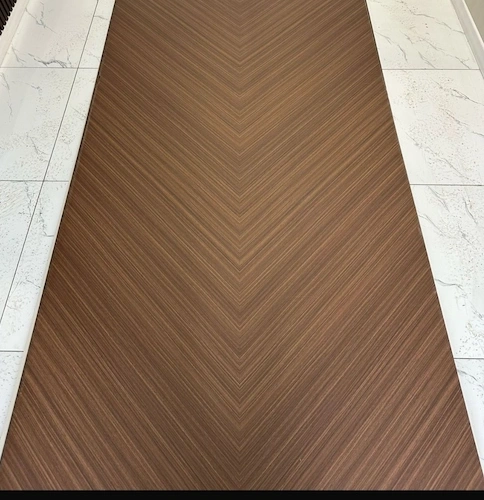

Surface treatment | Deep embossed, EIR, Crystal,Wood grain, Flat,Stone |

Material | 100% virgin material |

Click system | Unilin click system |

Installation Method | Floating |

SPC flooring loading | |

Pcs/ctn | 8 |

Weight(KG)/ctn | 14.5 |

Ctns/pallet | 75 |

Plt/20’FCL | 20 |

Sqm/20’FCL | 2716 |

Weight(KG)/G.W | 22300 |

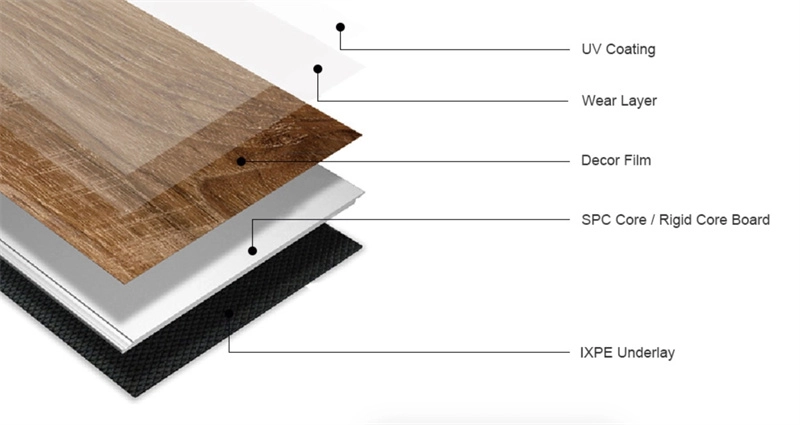

1. UV Coating

It enhances the clarity of the decoration film and resists fading.

2. Wear Layer

Scratch Resistance. For durability over 20 years. Widely used for residential areas, shopping malls, etc.

3. Decorative Film

Modern design based on the most popular models on the market.

4. SPC Rigid Core

It is made of superfine stone plastic composite material.

5. Underlayment (Optional)

It uses IXPE or EVA, can enhance the floor’s grip, fits existing surfaces, and reduces noise.

6. Click-Lock Installation System

Easy installation and making the floor sturdy and waterproof.

Characteristics | Test | SPC |

Dimension | ISO24341 | |

Thickness | ISO24346 | 5MM |

Wear Layer Thickness | ISO24340 | 0.2MM,0.3MM,0.4MM |

Weight | EN430 | 9.3KG/M2 |

Fire Resistance | En1350/ISO9239-1 | Clsss Bf1S1(B1) |

Dimensinal Stability | ISO23999 | ≤0.12% |

Color Fastness | ISO105-B02:1994 | ≥Grade6 |

Slip Resisitance | AS4586/DIN51130 | R10 |

Formaldehyde Emission | EN717-1 | E0 |

Curving | ISO23999 | ≤1.2MM |

Peel Resistance | ISO24345 | ≥75N/5CM |

Click Force | ISO24334 | ≥120N/5CM |

Anti-scratches | -- | ≥2500G |

Acoustic Performance | EN ISO 717-2 | Lw=10db |

Cigarette burn resistance | EN438-2 | Class 3 |

Castor Chair | ISO4918 | After 25000 cycles,no delamination occur.No disturbance to the surface other than a slight change in appearance |

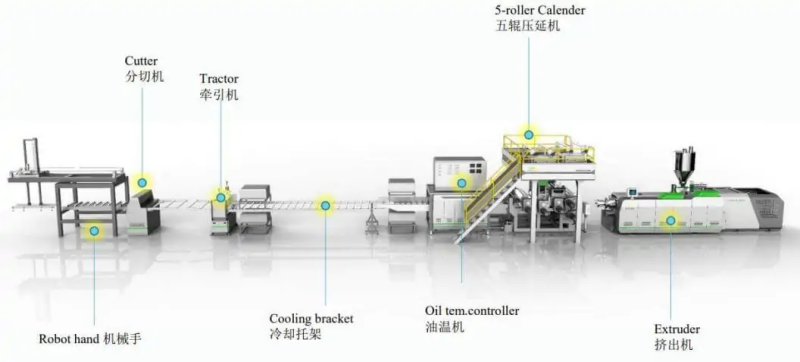

How SPC Flooring is Manufactured

1、Mixing Materials: PVC resin powder, plasticizer (DOTP), stabilizers (calcium/zinc), calcium carbonate, carbon black, and other additives are mixed according to a specific formula. The mixture is agitated for approximately 30 minutes, resulting in a homogeneous blend that is conveyed to the compounding machine for heating and mixing.

2、Extrusion: The powdered raw materials are fed into rollers, where they are gradually formed. The temperature during this process is approximately 170°C. The materials are then cooled and refined, forming the core and base layers, which are subsequently cut into 1x1m or 1x1.3m blocks.

3、Embossing: Layers of fabric, embossing plates, soft film (matte film, high-temperature paper), core/base materials, wear-resistant layer, decorative film, and another layer of soft film are sequentially laid on steel plates.

4、Hot Pressing: After placing another steel plate on top, the stack is subjected to continuous heating and pressing for approximately 40 minutes. After removing the soft film, the flooring is shaped and bonded firmly between layers.

5、UV Coating: The fully pressed flooring is placed on a conveyor belt and coated evenly with UV paint using rollers. It is then exposed to ultraviolet light and baked in an oven. This process involves two coats of UV paint and two rounds of ultraviolet exposure. The purpose is to enhance glossiness to meet customer requirements.

6、Annealing: Once the paint is fully cured, the flooring is cooled in cold water and dried using a cooler. Finally, it is placed in a normal temperature and state. Annealing helps strengthen the shrinkage and warping of the PVC flooring through heating and cooling on the production line.

7、Shaping the Flooring: The flooring is heated by machinery, making it easier to punch and shape into different forms.

8、Profiling: The flooring is analyzed according to customer specifications. Blade adjusters are used to modify the flooring dimensions. After adjustment, flooring fragments are placed on a conveyor belt and profiled along the long and short sides. The profiling machine ensures high precision for click products.

9、V-Groove Painting: After V-groove painting, the product texture appears more realistic, resembling wood grain.

10、Adding Soundproof Underlayment (if applicable): If SPC flooring includes an underlayment, it is added at this stage. The underlayment is placed at the bottom of the SPC core layer and pressed together through heating and pressure.

11、Quality Control: Completed flooring undergoes a quality control process to ensure that each piece meets the required standards. This includes checking for thickness, size, and color consistency.

12、Packaging: The flooring is inspected and cleaned one last time before being packaged. Scratches, impurities, dirt, bubbles, color variations, discoloration, white edges, delamination, folds, bevels, skew angles, and residual pieces are removed from non-conforming products. The boxes are sealed, labels are checked, and contents are accurately marked.

13、Shipping and Transport: Packaged flooring boxes are then loaded onto trucks or containers for transportation to distributors and retailers.

Work With Us

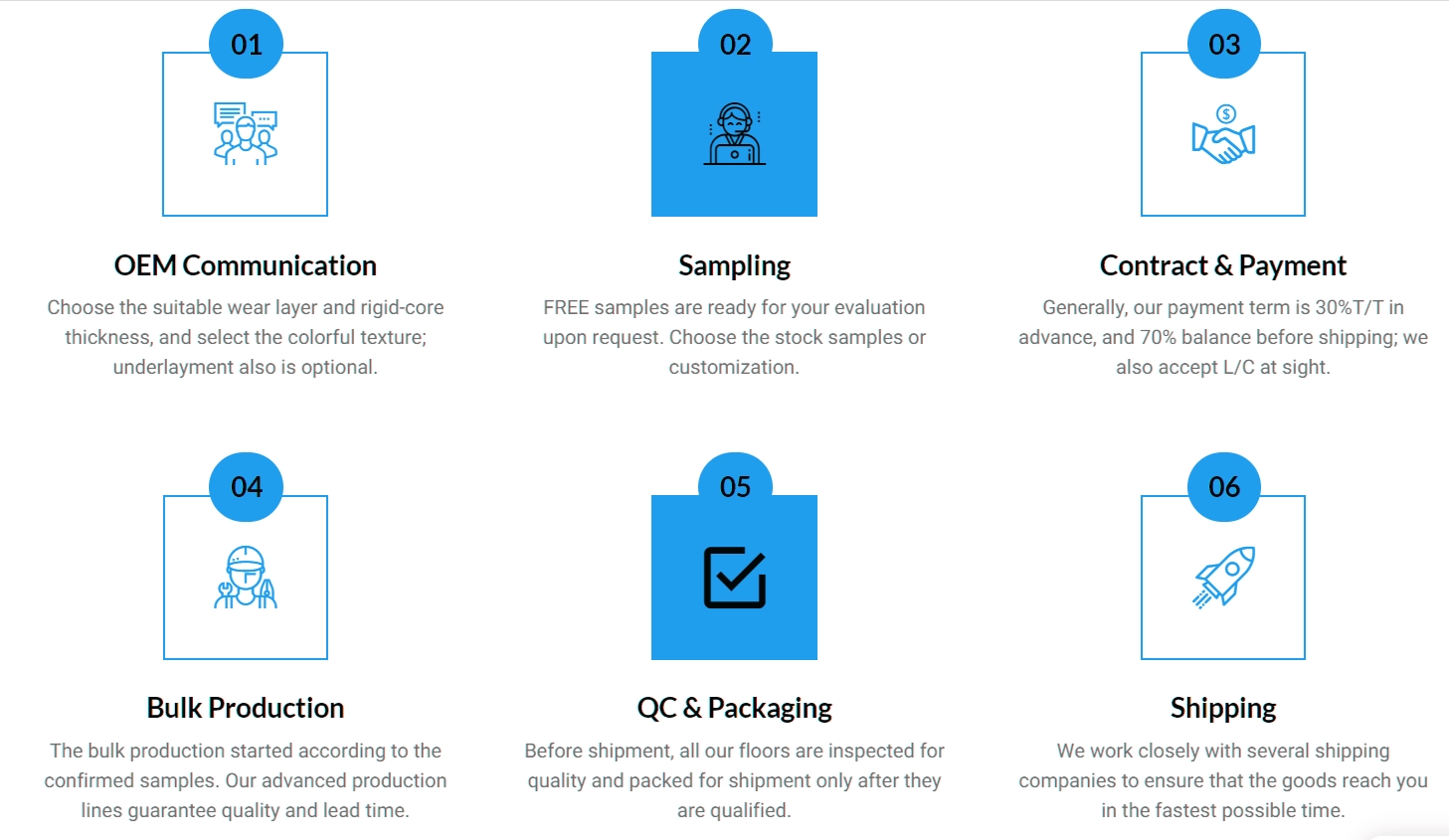

Our Working Proccess

305.webp)