What Is SPC Flooring

SPC flooring, a cutting-edge vinyl flooring solution, is engineered from stone polymer composite materials, ensuring exceptional durability and resistance to both moisture and wear. This innovative flooring option is highly favored in both residential and commercial settings due to its ease of installation and low maintenance requirements.

Our SPC flooring stands out for its superior quality, utilizing 100% virgin material to guarantee unparalleled durability and long-lasting aesthetic appeal. Crafted to meet stringent heavy-duty performance standards, our flooring not only delivers enduring beauty but also enduring functionality.

Why hesitate? Contact us today to request your complimentary samples and discover firsthand why our SPC flooring is a preferred choice among discerning customers.

SPC flooring specification | |

Color | Several hundreds of color available |

Thickness | 5mm SPC flooring |

Size: | 1200 x 184 mm, 915 x 150 mm, 930x310mm, etc. |

Top wearlayer | 0.3mm, 0.5mm |

Special treatment | Painted V-groove, soundproof IXPE |

Surface treatment | Deep embossed, EIR, Crystal,Wood grain, Flat,Stone |

Material | 100% virgin material |

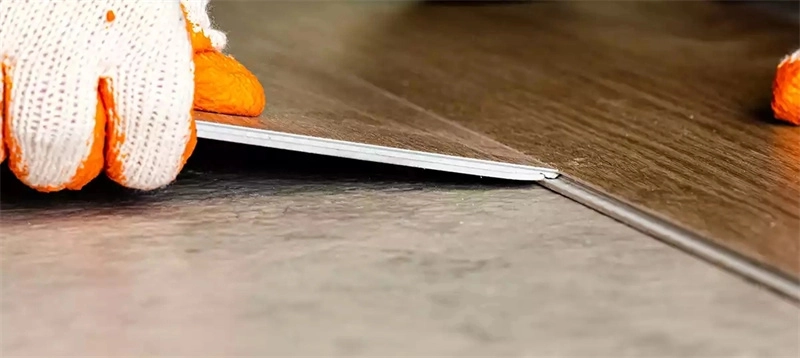

Click system | Unilin click system |

Installation Method | Floating |

SPC flooring loading | |

Pcs/ctn | 8 |

Weight(KG)/ctn | 18.5 |

Ctns/pallet | 60 |

Plt/20’FCL | 20 |

Sqm/20’FCL | 2173 |

Weight(KG)/G.W | 22300 |

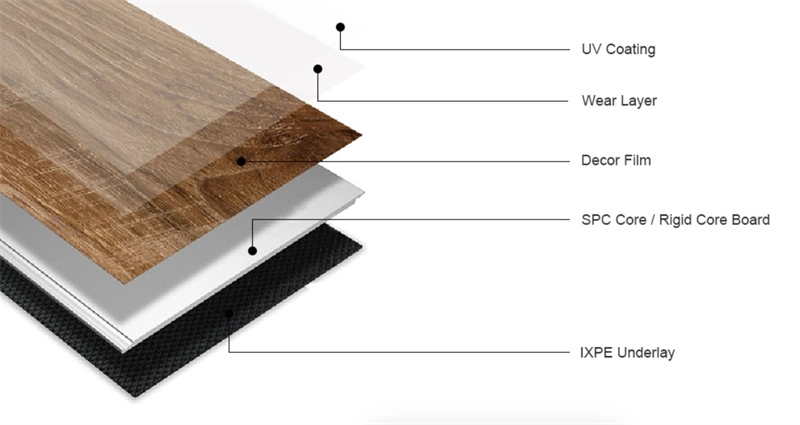

1. UV Coating

It enhances the clarity of the decoration film and resists fading.

2. Wear Layer

Scratch Resistance. For durability over 20 years. Widely used for residential areas, shopping malls, etc.

3. Decorative Film

Modern design based on the most popular models on the market.

4. SPC Rigid Core

It is made of superfine stone plastic composite material.

5. Underlayment (Optional)

It uses IXPE or EVA, can enhance the floor’s grip, fits existing surfaces, and reduces noise.

6. Click-Lock Installation System

Easy installation and making the floor sturdy and waterproof.

Characteristics | Test | SPC |

Dimension | ISO24341 | |

Thickness | ISO24346 | 5MM |

Wear Layer Thickness | ISO24340 | 0.2MM,0.3MM,0.4MM |

Weight | EN430 | 9.3KG/M2 |

Fire Resistance | En1350/ISO9239-1 | Clsss Bf1S1(B1) |

Dimensinal Stability | ISO23999 | ≤0.12% |

Color Fastness | ISO105-B02:1994 | ≥Grade6 |

Slip Resisitance | AS4586/DIN51130 | R10 |

Formaldehyde Emission | EN717-1 | E0 |

Curving | ISO23999 | ≤1.2MM |

Peel Resistance | ISO24345 | ≥75N/5CM |

Click Force | ISO24334 | ≥120N/5CM |

Anti-scratches | -- | ≥2500G |

Acoustic Performance | EN ISO 717-2 | Lw=10db |

Cigarette burn resistance | EN438-2 | Class 3 |

Castor Chair | ISO4918 | After 25000 cycles,no delamination occur.No disturbance to the surface other than a slight change in appearance |

SPC Flooring in China: Leading the New Trends in the Flooring Industry

With continuous innovations in technology and materials, China's SPC flooring is gaining prominence in the flooring industry with its unique advantages. This stone plastic composite flooring not only inherits the benefits of traditional flooring but also exhibits significant advantages in terms of environmental friendliness, durability, and aesthetics, making it a popular choice in the current interior decoration market

Environmental Advantages

China's SPC flooring has gained high recognition among consumers due to its environmentally friendly features. Its primary components include stone powder, polyvinyl chloride (PVC), and stabilizers, all of which are eco-friendly materials. It is free from harmful substances like formaldehyde, in compliance with national environmental standards. Choosing SPC flooring for interior decoration not only safeguards the health of your family but also contributes to creating a fresh and comfortable living environment.

Wear and Tear Resistance

China's SPC flooring stands out with its outstanding wear resistance, capable of withstanding high-intensity use in daily life. Whether in commercial spaces or home renovations, SPC flooring maintains its appearance, is less susceptible to scratching or wear, and offers reliability for long-term use.

Waterproof and Moisture-Resistant

In humid environments, China's SPC flooring exhibits its unique advantages. Whether in the kitchen, bathroom, or laundry room, SPC flooring maintains its stability. It does not deform or warp due to exposure to moisture, providing a reliable solution for home renovations.

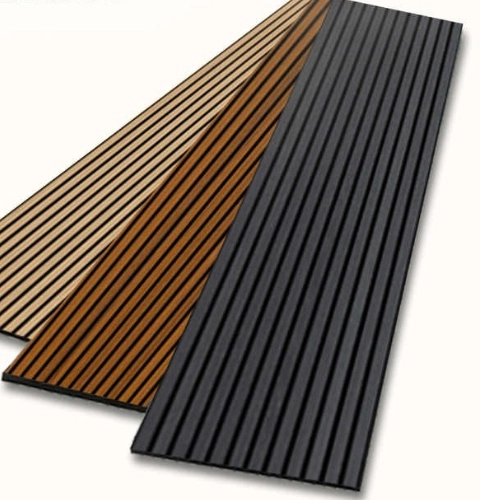

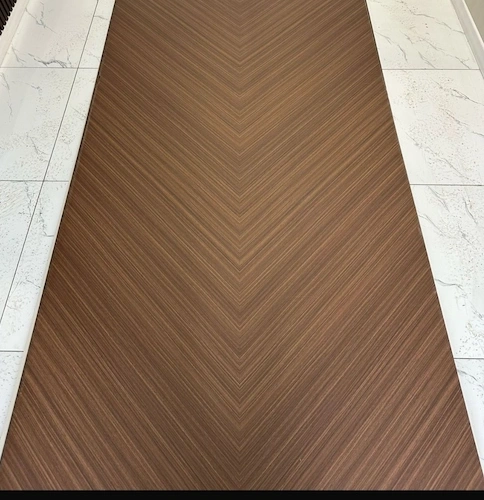

Diverse Designs and Patterns

China's SPC flooring offers a high degree of design freedom, as it can mimic various materials such as wood grain and stone patterns. It meets the needs of different interior design styles. Consumers can choose the most suitable style based on their preferences, making interior decoration more personalized.

Convenient Installation and Maintenance

SPC flooring employs a click-lock installation design, eliminating the need for adhesives or glues, making the installation process convenient and quick. Its smooth surface is less prone to dust accumulation, making maintenance relatively straightforward, saving time and effort in home renovations.

In summary, China's SPC flooring is becoming a leader in the flooring industry, thanks to its excellent performance and environmental features. In today's interior decoration market, choosing SPC flooring not only meets the needs of home renovations but also represents a proactive choice for health and environmental considerations. With ongoing technological advancements, we believe that China's SPC flooring will continue to play a crucial role in the flooring industry, providing more comfort and convenience to people's home life.

Why Choose Us

Our Experience in Vinyl Flooring Manufacturingdates back to 15 years ago

We are passionate about providing our customers with high-quality vinyl flooring , We use the latest technology and equipment to create various colors and styles to meet customers’ needs.

*Best Quality Standards

*100% Satisfaction Guarantee

*Quality Control System

*Commitment to Customers

*Highly Professional Team

*Best virgin Materials

How is SPC flooring made?

SPC (Stone Plastic Composite) flooring is a type of rigid core vinyl flooring that is engineered for stability and durability. It's made from natural limestone powder, polyvinyl chloride, and stabilizers. Here's how SPC flooring is made:

Raw Materials: The primary components of SPC flooring are natural limestone powder, polyvinyl chloride (PVC) resin, stabilizers, and pigments for color. These materials are carefully measured and mixed according to a specific formula.

Mixing: The limestone powder and PVC resin are mixed together thoroughly to form a homogenous mixture. This mixture provides the flooring with its rigidity and stability.

Extrusion: The mixed material is then fed into an extruder, which shapes the flooring planks. The extruder applies heat and pressure to the mixture, forming it into the desired plank shape. During this process, decorative patterns and textures can be embossed onto the surface to mimic the look and feel of natural materials like wood or stone.

Calendering: After extrusion, the planks go through a calendering process where they are heated and pressed between rollers. This step further enhances the plank's stability and thickness uniformity.

UV Coating: A UV-resistant coating is applied to the surface of the SPC planks. This coating protects the flooring from fading and wear caused by sunlight and daily use.

Cutting: The continuous sheets of SPC flooring are cut into individual planks of various sizes. Precise cutting ensures that the planks have straight edges and consistent dimensions.

Quality Control: The finished SPC planks undergo quality control checks to ensure they meet the desired standards in terms of dimensions, appearance, and overall quality.

Packaging: Once the quality control checks are complete, the SPC flooring planks are packaged and prepared for shipping.

Work With Us

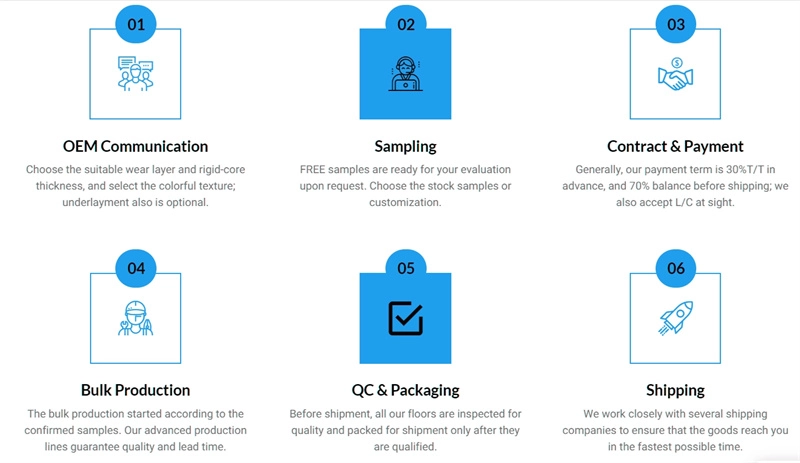

Our Working Proccess

305.webp)